#477, Preah Monivong Boulevard (Street 93), Sangkat Boeng Prolit, Phnom Penh, Phnom Penh Cambodia.

The DF350A/DF325A/DF300B is equipped with a dog-leg shaped dual louver at the air intake to completely remove water from the air taken into the cowl.

It helps to protect the engine from water in the fuel using a water detecting fuel filter to alert the driver with both visual and audio warnings when water is present in the fuel.

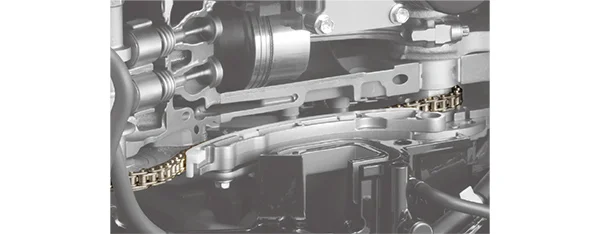

The timing chain runs in an oil-bath so it never needs lubricating, and is equipped with an automatic hydraulic tensioner so it remains properly adjusted at all times.

The engine’s cooling system relies on water supplied through two water inlets located on the lower unit where usually there is only one.

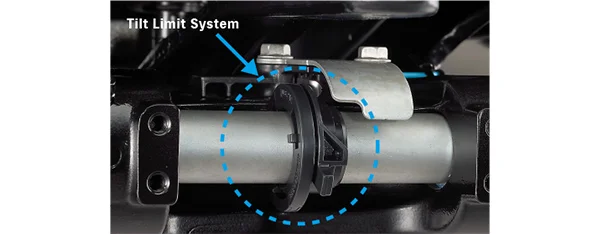

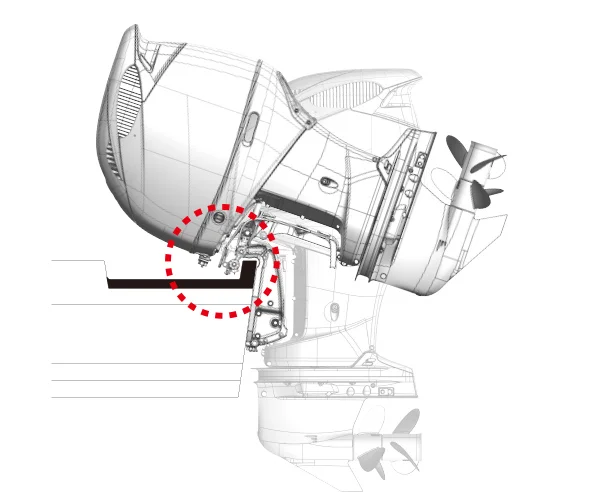

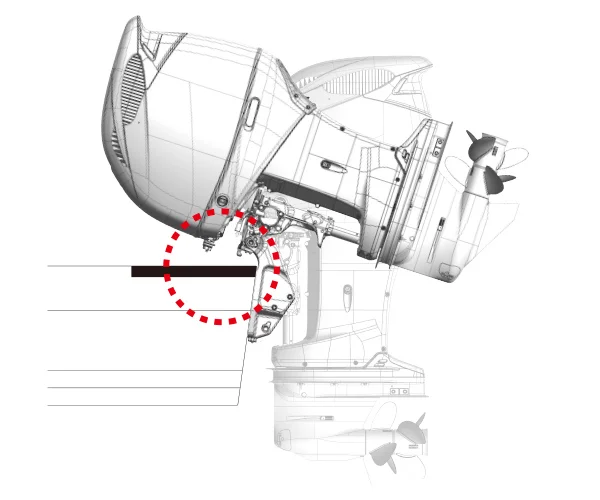

Tilt Limit System prevents the outboard from tilting beyond a selected angle.

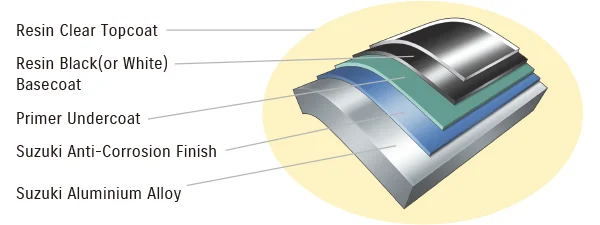

Special protection is applied to the aluminum surface using high strength bonding to protect the aluminum made exterior parts.

This system allows you to start the engine by having the key-fob nearby.

Two water inlets in different directions ensure that the engine does not overheat due to the clogging of algae.

This app enables you to make a plan for boating with the weather forecast and check the engine condition & operation tips for the next boating. All functions are available for free.* Please check the details from here.

The engine powerhead is positioned closer to the front, moving the outboard’s center of gravity forward.

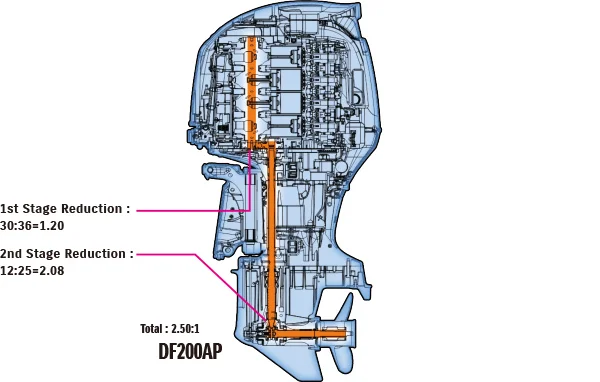

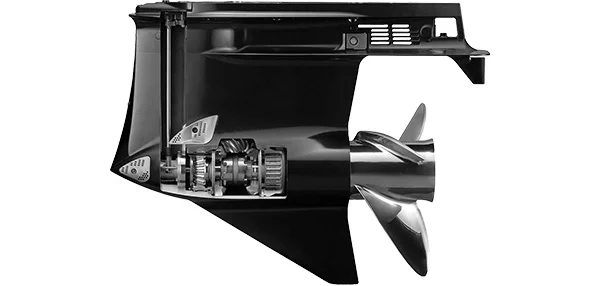

This system which incorporates the Offset Driveshaft features a first stage reduction between the crankshaft and drive shaft, and a second stage reduction inside the gear case. This design makes a larger gear ratio possible, allowing it to turn a large diameter propeller.

| MODEL |

DF140BG/115BG/ DF140A/115A/100A DF100B/90A/80A/70A DF90AWQH |

DF200A(AP)/ 175A(AP)/150A(AP) DF150W |

DF250/ 225/200 |

DF300AP/ 250AP DF250W |

DF350A/ 325A/300B |

|---|---|---|---|---|---|

| GEAR RATIO |

2.59:1 | 2.50:1 | 2.29:1 | 2.08:1 | 2.29:1 |

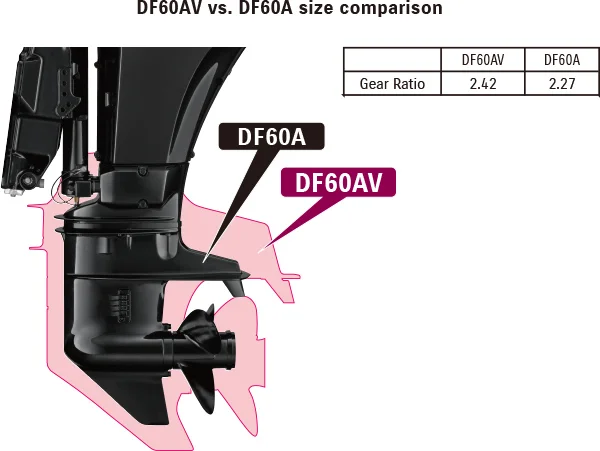

These outboard motors are equipped with gears designed with a 2.42 gear ratio, which is larger than the standard model, in their lower units. When combined with a large 36cm (14-inch) propeller, the powerful system can deliver an explosive forward thrust. This is ideal for heavy boats.

The Suzuki Dual Prop System spins two propellers rotating in opposite directions on a single engine.

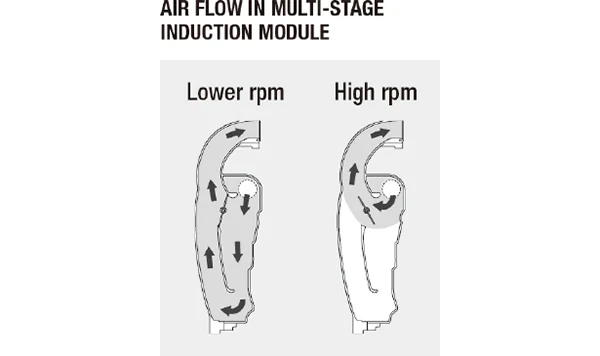

Manifold pipes are switched between short and long during low speed and high speed operation to ensure the right volume of air enters the engine.

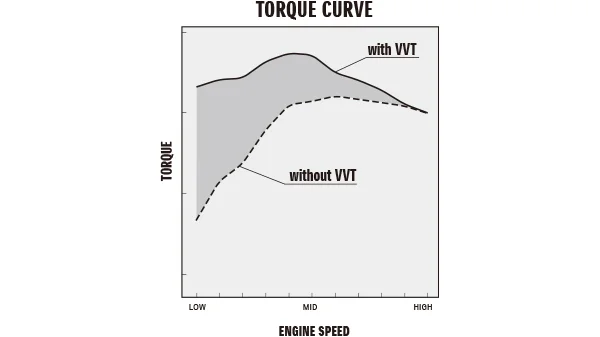

The Variable Valve Timing is used to control the opening and closing timing of the intake valve depending on the engine operation.

Designing a direct airflow path from the intake port to the cylinder suppresses any increase in the intake temperature and improves combustion efficiency.

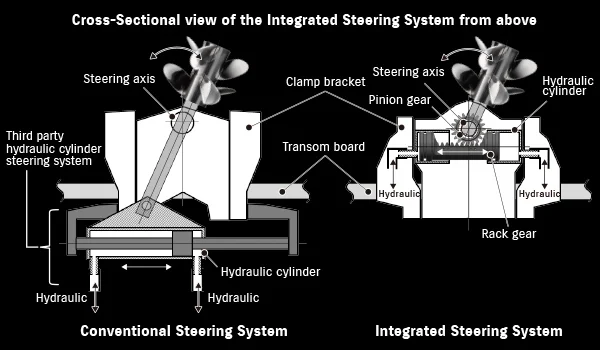

The conventional external hydraulic cylinder is built into the outboard motor.

Operation from the remote control is delivered to the outboard via an electric signal and not by the traditional mechanical control cables.

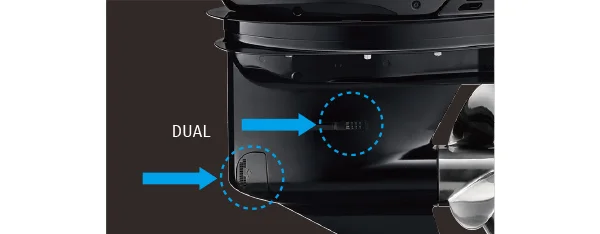

Function for selecting regular or counter rotation on one outboard with an optional connector and a counter rotation propeller.

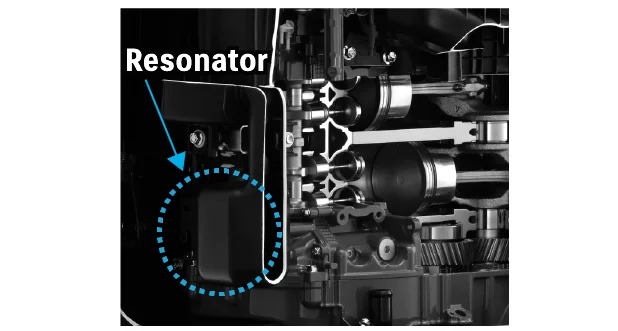

Intake noise is suppressed with silencer and resonator, which makes the noise from the outboard quieter.

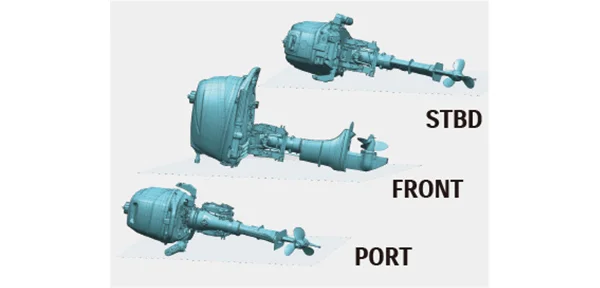

The design allows the outboard to be removed from the boat and placed on any of its 3 sides for storage.

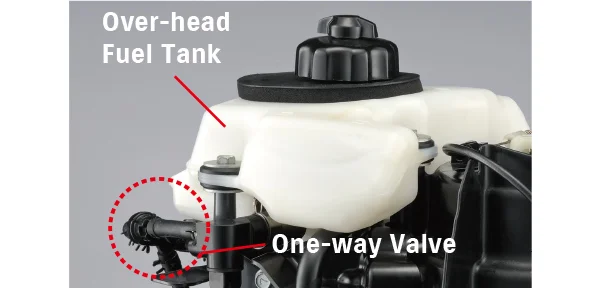

The integral overhead fuel tank and one-way valve delivers fuel supply by using gravity.

This system helps the boat running at a certain speed range in low revs.

* Available with SMG or Troll Mode Switch Panel

Enables the outboard motor to be tilted up or down quickly with minimal force.

The Automatic Trim adjust trim angle automatically depending on the engine RPM without your control.

* Available with SMG4

Enjoy this function with SMG4. You can find how to use it from the video.

Simply turn the key and release, and the starter stays engaged until the engine starts. This system offers a smoother start of the engine.

The Lean Burn Control System supplies the appropriate amount of fuel and air mixture depending on the navigation conditions.

It helps to protect the engine from water in the fuel using a water detecting fuel filter to alert the driver with both visual and audio warnings when water is present in the fuel.

The dual injector delivers just the right amount of fuel at the right time into each cylinder.

As one of the actions in SUZUKI CLEAN OCEAN PROJECT, we developed the device to collect micro-plastics in the oceans just by running SUZUKI's outboard motors.

The Innovation Awards (recognizing technological innovation) granted each year by the NMMA (National Marine Manufacturers Association) are considered among the highest honors in marine technology. Of the new marine industry products in that year, they are awarded to “a product that shows technical leadership, is practical and cost-effective, and is truly beneficial to the consumer.” Starting with the DT200 Exanté in 1987 and extending to the DF350A in 2017, Suzuki outboard motors have received this Innovation Award a total of nine times. Eight of these awards have been for 4-stroke outboard motors, which is the largest number of awards in the engine category in the industry.

Awarded Prizes 1987: DT200 Exanté / 1997: DF70 & DF60 / 1998: DF50 & DF40 / 2003: DF250 / 2006: DF300 / 2011: DF50A & DF40A / 2012: DF300AP / 2014: DF30A & DF25A / 2017: DF350A